-

About

-

Products

- By Timber Product

- Cladding

- Decking

- Joinery

- Screening

- Panelling

- View all

- By Application

- Exterior Cladding / Siding

- Exterior Rain Screen

- Exterior Roofing

- Interior Walls & Ceilings

- Soffits

- Screening, Fins & Battens

- Windows, Doors & Joinery

- Posts & Beams

- Accessories

- Coatings

- Fixings

-

Resources

- By Resource Type

- Technical Data Sheets

- Guides & Manuals

- Technical Articles

- Profile Drawings

- View all

- How To

- How to Specify

- How to Install

- How to Maintain

- Projects

- Contact

HOLIDAY HOURS / Our online customer service is out of office from Friday 19 Dec - Monday 5 Jan. Learn more here.

How Thermally Modified Timber Performs when Exposed to Moisture

Thermal modification is known to improve dimensional stability, so how does our timber compare to other species and products?

A recent report by Crown research institute Scion answers this question by analysing results from two moisture exposure tests, which were performed on thermally modified radiata pine and a range of other commercially available wood types.

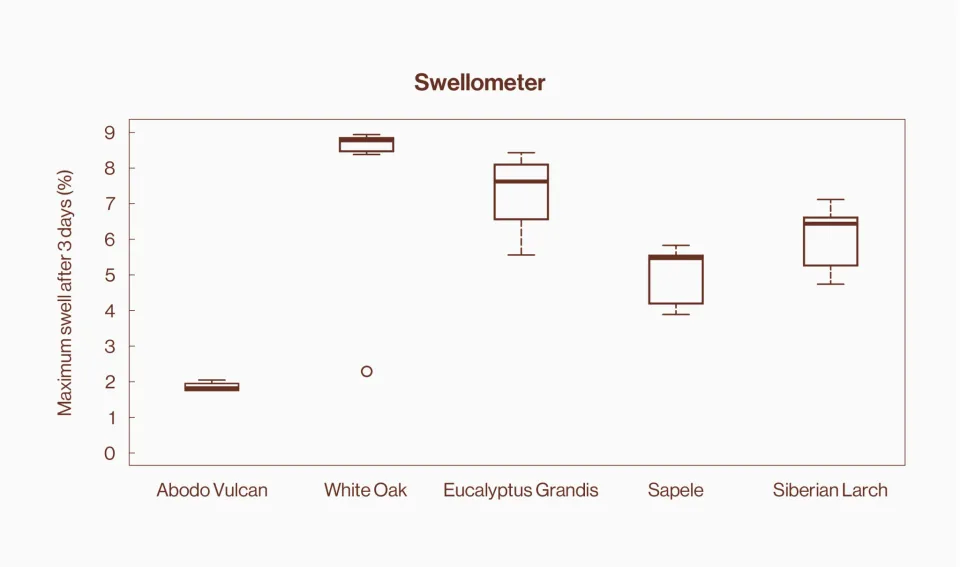

The report compares the results from a Swellometer, which involves soaking timber in water for three days, and a Long Term Humidity Cycling test, which exposes the timber to a range of low and high humidity environments.

The Swellometer test takes continuous measurements of radial and tangential dimension in the timber – or in layman’s terms, how much the timber swells – while the Long Term Cycling test checks for movement in grain direction during altered humidity levels, effectively ascertaining how much the timber changes shape through this exposure.

The species and products tested were as follows: Locally sourced Unmodified radiata pine; Abodo Vulcan thermally modified radiata pine; Accoya (acetylated) radiata pine; Kebony (furfurylated) radiata pine; Western red cedar; Victorian ash; White oak; Cupressus lusitanica; as well as internationally sourced Eucalyptus grandis, Siberian larch and Sapele, which were added to the Swellometer test only.

Findings in brief

Results from the Swellometer showed that Abodo’s thermally modified radiata pine swelled substantially less than unmodified radiata, and around the same amount as the Kebony, Accoya, and Western red cedar samples. Other samples, such as the White oak and Eucalyptus, swelled to significantly higher levels.

In the Long Term Humidity Cycling, Abodo's thermally modified radiata displayed lower dimension changes than its Unmodified counterpart, and swelled less than Western red cedar. Swelling levels in the Kebony and Accoya were lower than the thermally modified radiata.

In summary, the tests showed that Abodo Vulcan thermally modified radiata pine performs at a similar level to Western red cedar when exposed to both soaking and humidity changes. This is a positive result, since Western red cedar is known for its stability.

These are especially significant findings for those looking at specifying Abodo Vulcan timbers for windows and doors. Poor dimensional stability is associated with issues such as surface checking, difficulty with paint adhesion, cracking and loosening of joints and glue lines. This report shows that thermal modification improves the dimensional stability of wood, reducing the occurrence of these issues for lasting performance in all weathers.

Download the report for a more detailed overview of the figures and findings.